Call us: +44 (0)1625 874598 Email us: sales@pumptech.co.uk

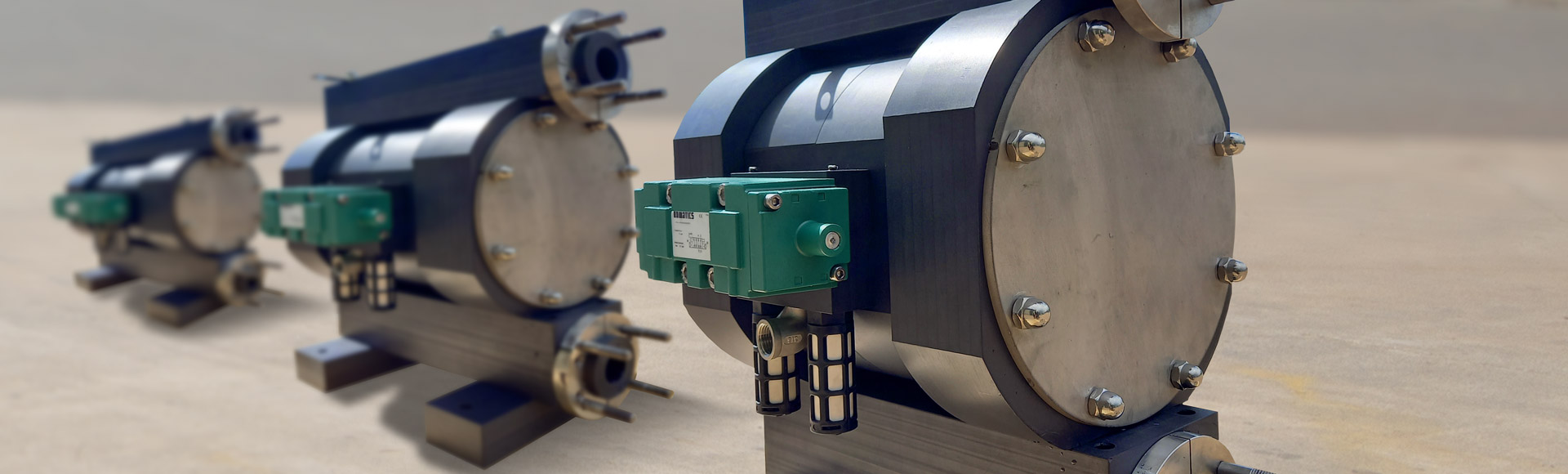

For over 20 years, Pumping and Technical Services have produced a range of air-operated diaphragm pumps available in Polypropylene and PTFE materials with EP, Viton, Neoprene and PTFE diaphragms.

Manufactured by us here in the UK, this range of diaphragm pumps is distributed under the Centurion brand.

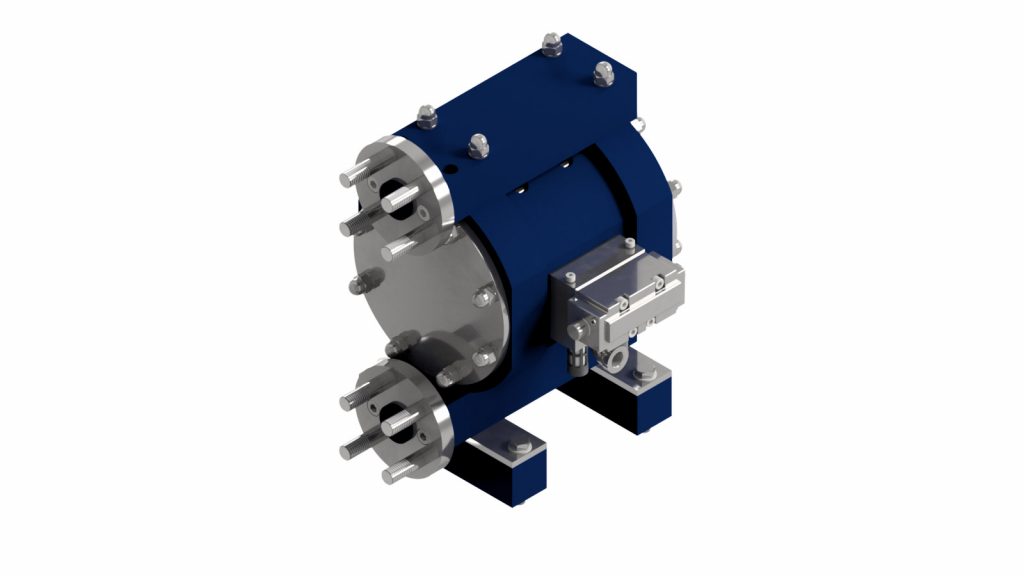

These pumps are machined from solid block materials for maximum strength and chemical resistance. They are without dynamic seals and glands therefore there are no fluid or vapour leakages which make them ideal for corrosive and abrasive chemicals. There are no exposed metal parts and they can be configured in various materials to meet most abrasion, temperature, and chemical compatibility requirements. Perfectly designed for ATEX environments.

Centurion Diaphragm Pump

The Centurion is available in four sizes with flow rates up to 25m3/hr.

| Size S: ½” (12.5mm) connections | Size A: 1″ (25mm) connections |

| Size B: 1½” (40mm) connections | Size C: 2″ (50mm) connections |

- Machined from solid block material.

- Choice of diaphragm material.

- Self-priming.

- Able to run dry without damage.

- Ex Stock – PTFE or Polypropylene construction.

- ATEX version available.

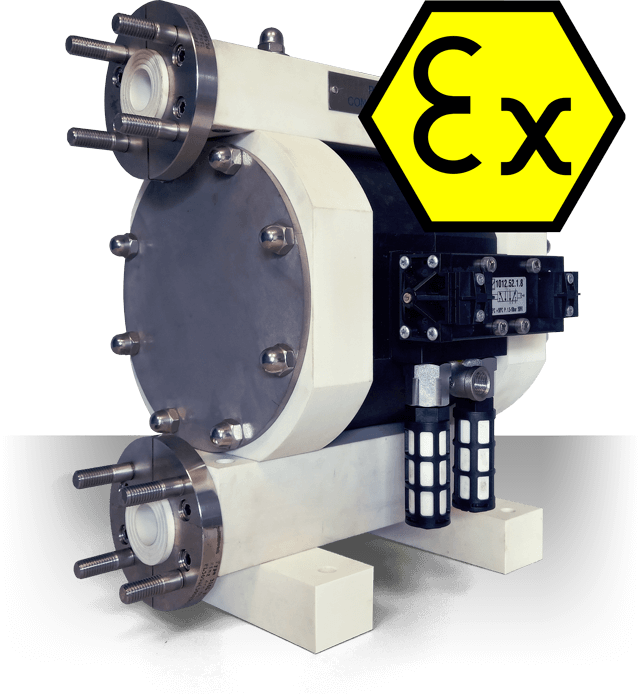

ATEX

Operation is from standard compressed air supply at up to 100psi supply rating. Pumps can be supplied ATEX compliant for zoned areas. The solid block conductive (carbon filled) material ensures that no electrostatic loads will accumulate within the pump. An earth connection is mounted on the pump, for earthing of electrostatic loads.

The PATS’ Centurion diaphragm pumps can be made to order for special duties and custom materials such as titanium, stainless steel or any customer requirement available on request.

Made in Britain – Exported Worldwide

All of our pumps are custom manufactured at our extensive facility in Adlington, South Manchester by highly experienced staff who have been at the forefront of pump design and manufacture for over 40 years.

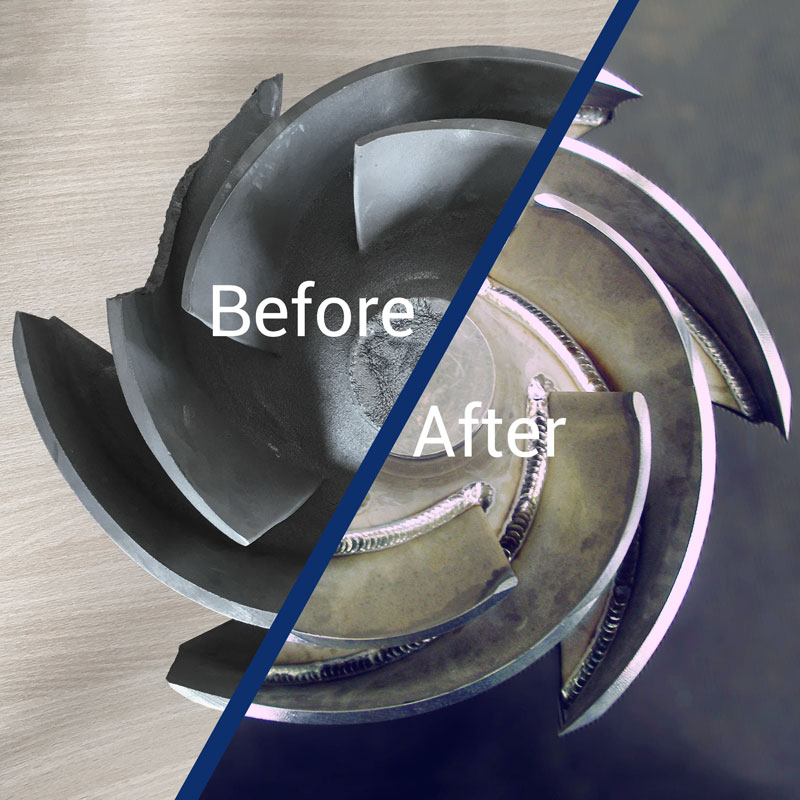

Need Servicing?

As well as manufacturing, PATS also offer comprehensive pump servicing and testing facilities. Strip & report, spare parts supply, reverse engineering, refurbishment, problem analysis and warranty work.

Can we help?

If you would like to discuss an upcoming project with PATS and take advantage of an extensive knowledge base to resolve a specific pump related issue, please get in touch and our team of specialist pump engineers will be happy to help.