Call us: +44 (0)1625 874598 Email us: sales@pumptech.co.uk

Many of our customers do not want to invest in new capital equipment because replacement parts of the original pump are discontinued and no longer available. Additionally, when an emergency breakdown situation or routine maintenance service highlights the urgent need for replacement parts the long lead times for OEM parts may not be tolerable.

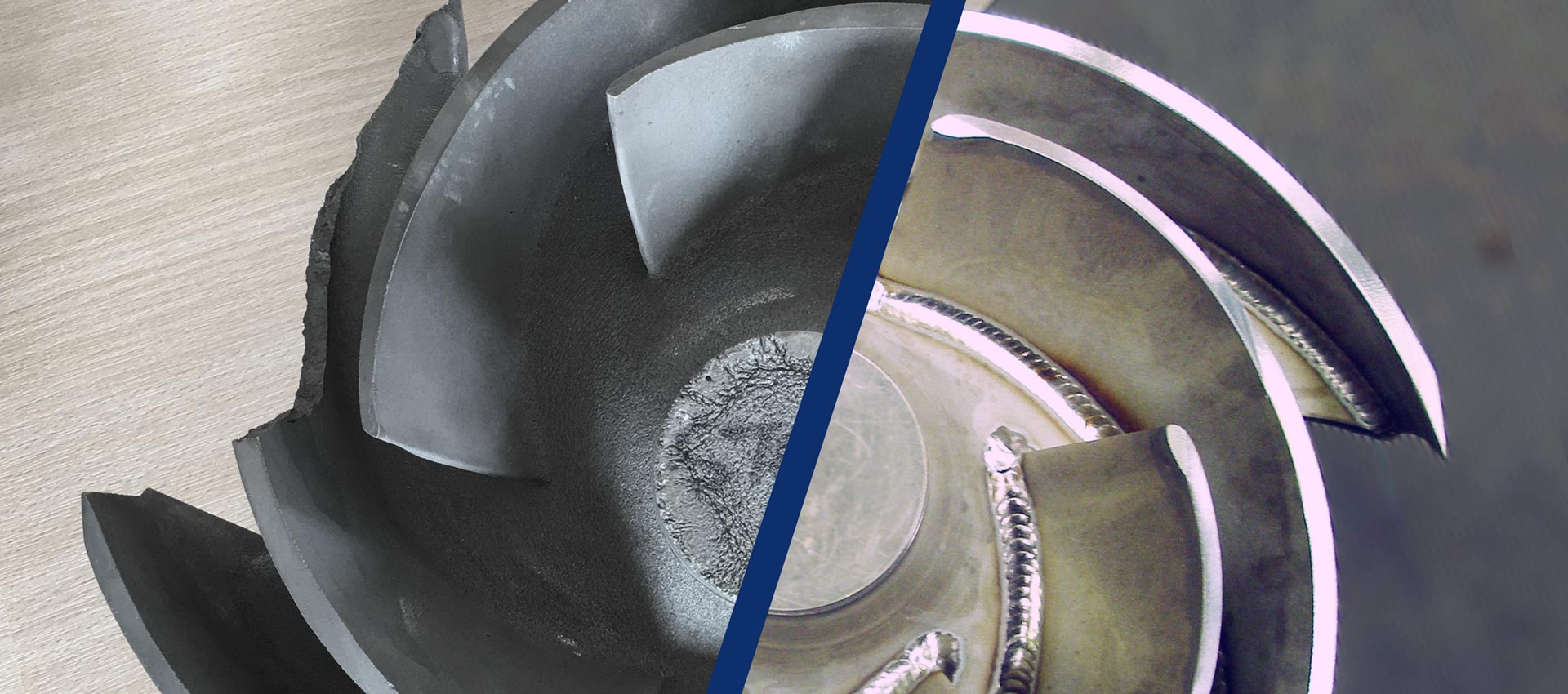

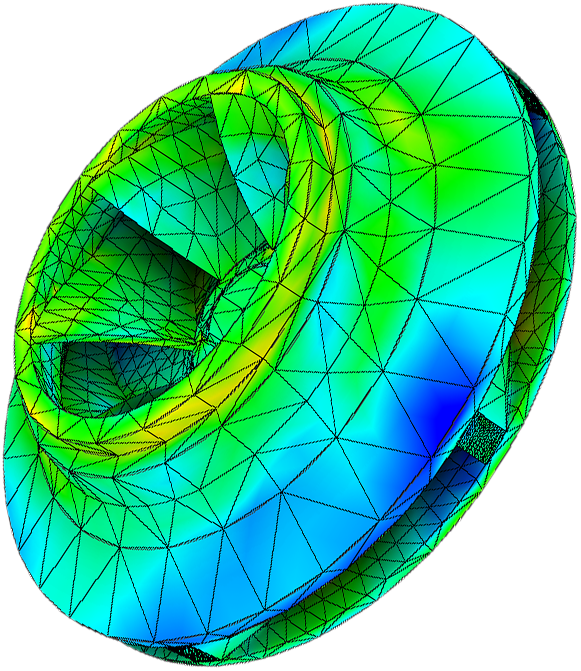

Pumping and Technical Services aftermarket service can replicate and manufacture any worn out or broken pump parts for most makes and models of pump. The returned pumps are fully inspected by our engineers and required parts modelled using the latest modelling software. If the failure mode is a common occurrence PATS can also offer improvements in component design or materials of construction to greatly improve both the hydraulic performance and service life of the equipment.

All repaired pumps are then fully performance tested at our test facility to prove the re-work prior to being returned to site.

Can we help?

If you would like to discuss an upcoming project with PATS and take advantage of an extensive knowledge base to resolve a specific pump related issue, please get in touch and our team of specialist pump engineers will be happy to help.