Call us: +44 (0)1625 874598 Email us: sales@pumptech.co.uk

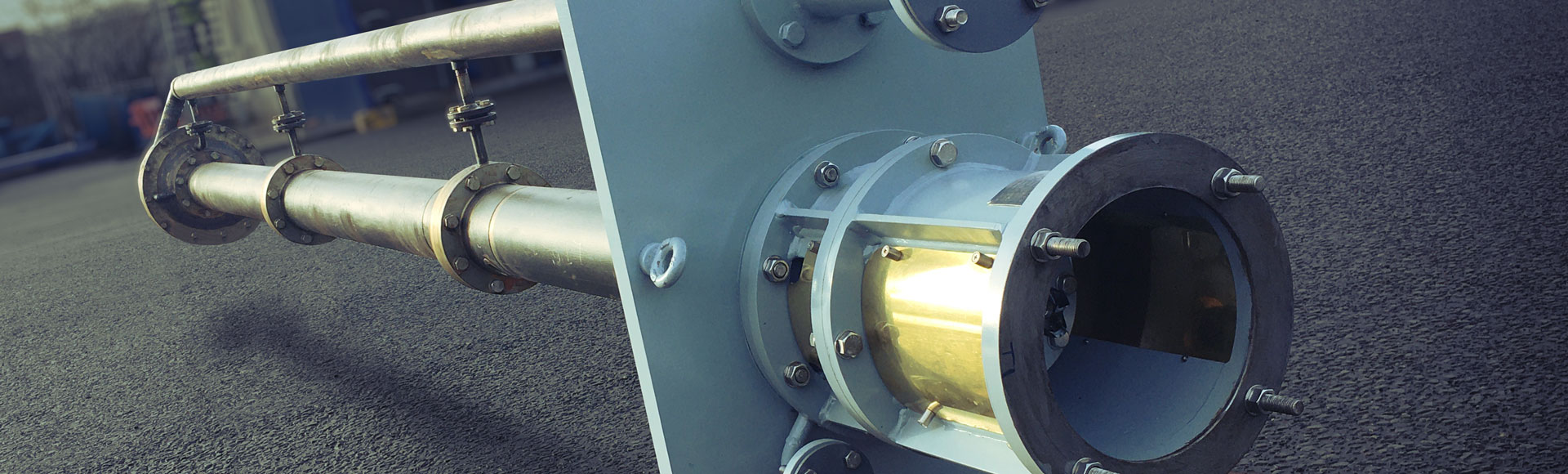

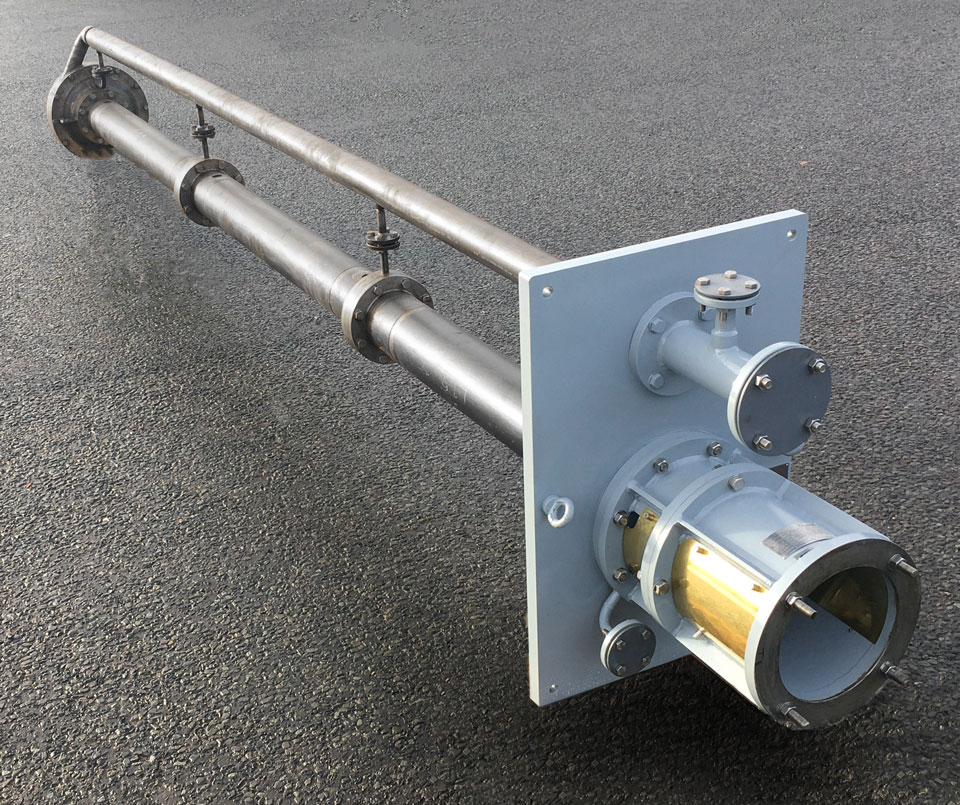

A major area of PATS’ expertise is in the design and manufacture of fully steam jacketed pumps for molten sulphur, salts and metals. Over many years PATS has constantly refined the features incorporated based on operational experience and customer feedback.

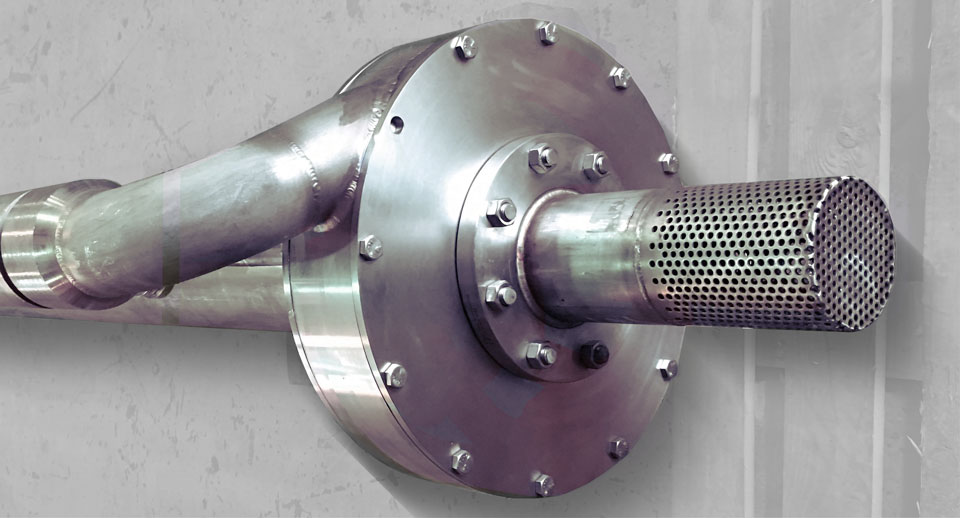

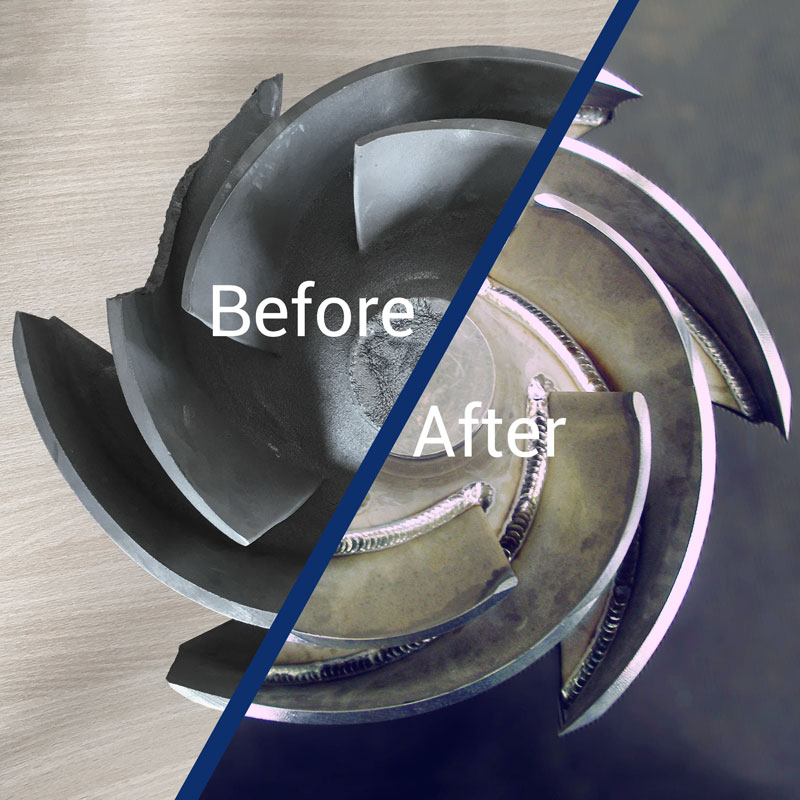

Pump are designed when required to API 610 11th Edition specifications and are generally of fabricated construction using machined from solid material techniques, form milled from certified billet, plate and bar materials. This gives a much greater hydraulic end thickness with up to five times denser and homogenous structure, far stronger and longer lasting than the cast components offered by our competitors. This also eliminates any casting failure, cold shuts, core shift and porosity issues giving a much greater service life over cast component equivalents.

Units can be supplied in Horizontal or Vertical format for Sulphur transfer loading, storage or sump duties and both formats incorporate beneficial features which improve operational efficiency and long maintenance free operation in service.

Design Features

Shafting

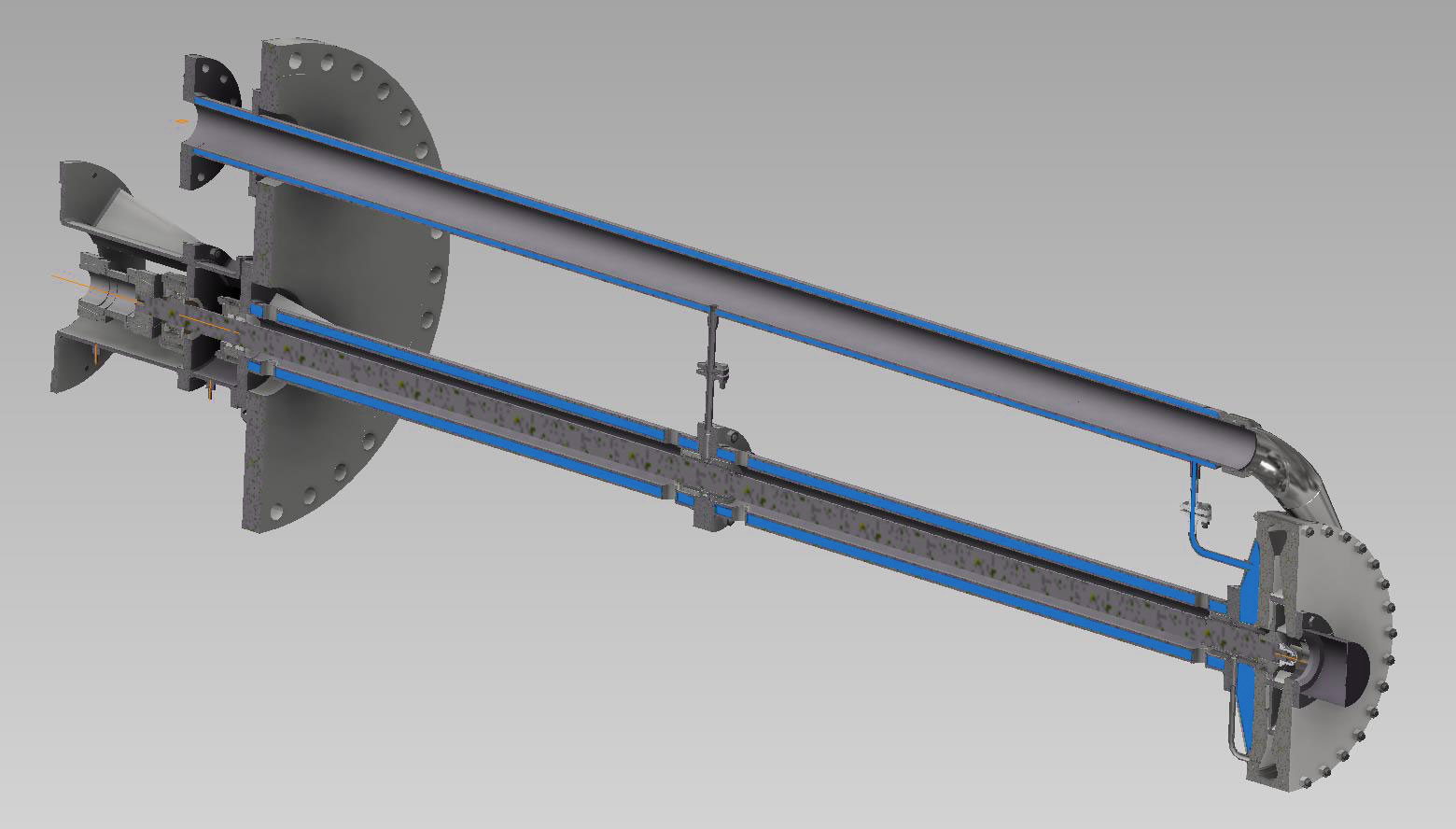

Shaft diameters for VS4 Vertical pumps are kept to 60mm as a minimum and are of ‘stiff shaft’ design to ensure the unit does not pass through first critical speed to reach its operating speed. API 610 maximum spacing between line shaft bearings is adhered to as a minimum, frequently PATS’ inter-bearing spacing is shorter. One-piece shafts are available to 4m lengths, for longer applications, two-piece construction would be offered with properly engineered keyed shaft couplings. This all has a positive effect to minimise vibration levels and extend the lifespan of the unit.

Line shaft bearings feature a unique fully floating bush design which evens out any wear over the entire bush surface and greatly extends line shaft bearing lifespan. Bushes are positively fed from fully steam jacketed discharge pipework to ensure non-interrupted lubrication. The steam supply also flows right through the columns and the inter-bearing housing itself, again ensuring superior heating and preventing the possibility of any cold spots which could potentially cause blockage and lubrication starvation to the line shaft bearings.

Steam Jacketing

All units include extensive steam jacketing which is fully integral into the pump wet-end design which is technically superior, stronger and longer lasting than cast-in, weld on, or bolt on jackets which are always an inferior compromise designed to fit a standard wet end design casting.

PATS integral design eliminates any cold spots within all areas of the pump which could potentially lead to problems during operation such as inter-bearing starvation and blockages. This fully jacketed design eliminates any sulphur retention and enables the sulphur to be fully drained down when the unit is removed for maintenance and servicing.

Impellers

Fully open impellers are considered mandatory in PATS molten sulphur pump design, preventing any potential hydraulic end blockages as there are no fine clearances or narrow passageways, common in standard shrouded impeller designs, this open impeller design makes all PATS units extremely tolerant of entrained solids and gas, with the added ability of being able to accommodate viscosity variation, a common requirement on molten sulphur applications.

Shaft Sealing

For vertical units vapour sealing is effectively controlled by a simple stuffing box arrangement with rings of dry-running packing. Other mechanical seals and systems can be incorporated used in accordance with customer requirements including if the service is sour. From single mechanical seals, double arrangements with barrier systems and dry-running gas seals all being available. On vertical units the main support column has been designed with spill-back holes to allow liquid to flow back to the vessel or pit, thus ensuring that the top shaft sealing is confined to vapours only, not liquid.

Mounting Plates

Mounting plates can be designed and offered to meet clients exact requirements at site from circular ANSI flange arrangements to rectangular designs to suit the sump opening.

Can we help?

If you would like to discuss an upcoming project with PATS and take advantage of an extensive knowledge base to resolve a specific pump related issue, please get in touch and our team of specialist pump engineers will be happy to help.

Made in Britain – Exported Worldwide

All of our pumps are custom manufactured at our extensive facility in Adlington, South Manchester by highly experienced staff who have been at the forefront of pump design and manufacture for over 40 years.

Need Servicing?

As well as manufacturing, PATS also offer comprehensive pump servicing and testing facilities. Strip & report, spare parts supply, reverse engineering, refurbishment, problem analysis and warranty work.