Call us: +44 (0)1625 874598 Email us: sales@pumptech.co.uk

Whilst the basic hydraulic and mechanical aspects of our pumps are from established parameters, each unit is custom engineered to suit our clients’ process application. This flexible approach ensures the optimum features essential for trouble free, low maintenance installation.

Hydraulic ends are designed for heavy duty service with thicknesses ample to cater for corrosive service. Generally manufactured in “milled-from-solid” format using certified billet materials, the resulting dense material eliminates casting failures and porosity, giving greater service life, whilst still being competitively priced.

Casings of concentric, single volute and double volute designs, impellers of open, semi-open and shrouded designs are all available, as are recessed ‘vortex’ designs to handle large solids concentrations, or for ‘low-shear’ applications. All designed to give minimum NPSH requirements.

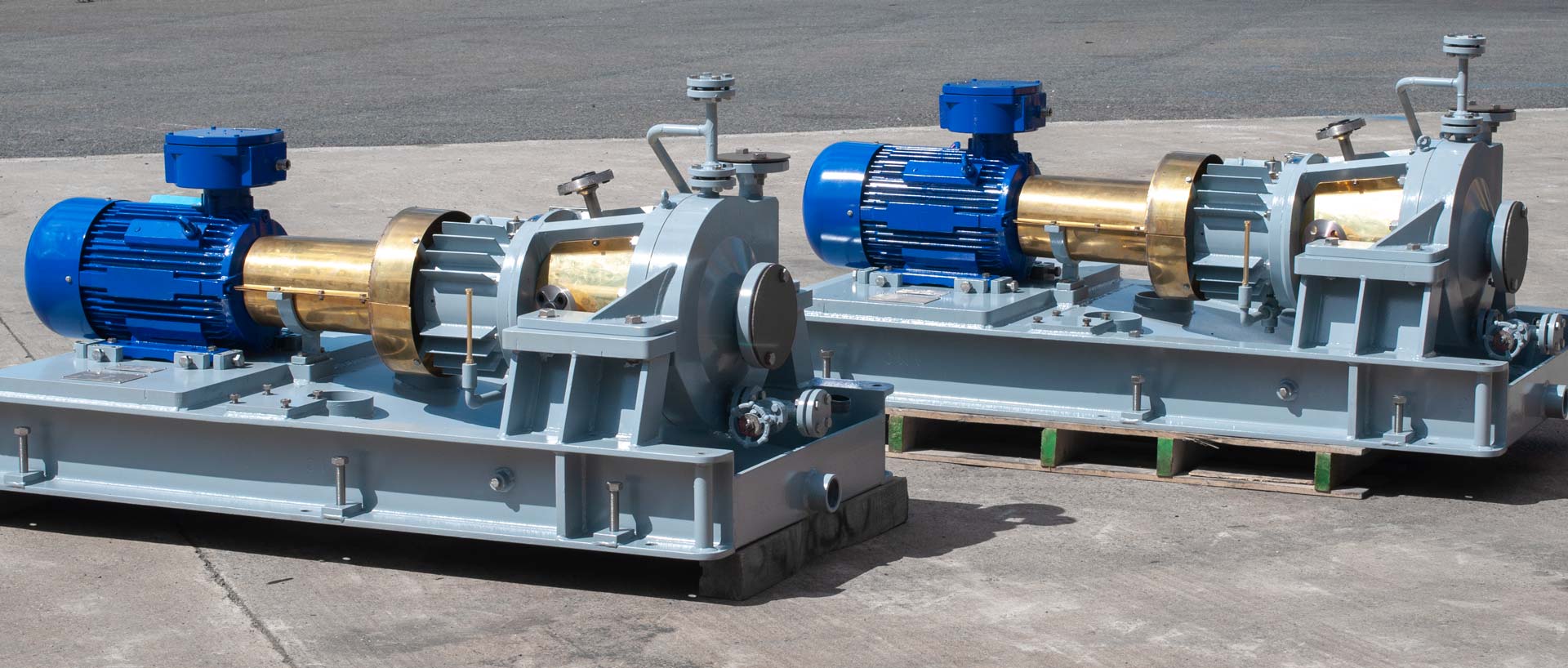

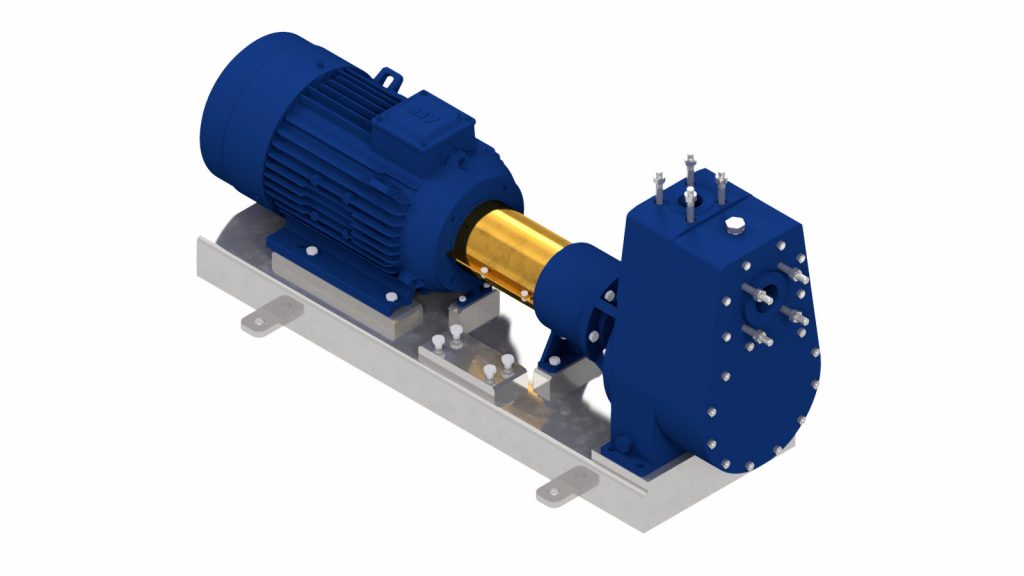

API 610 Horizontal Centrifugal Process Pumps

- API610 11th Edition compliant.

- OH1 horizontal foot mounted.

- OH2 horizontal centreline mounted.

- Single stage end suction.

- Long coupled.

- Various impeller variations – shrouded, semi-open, open and recessed.

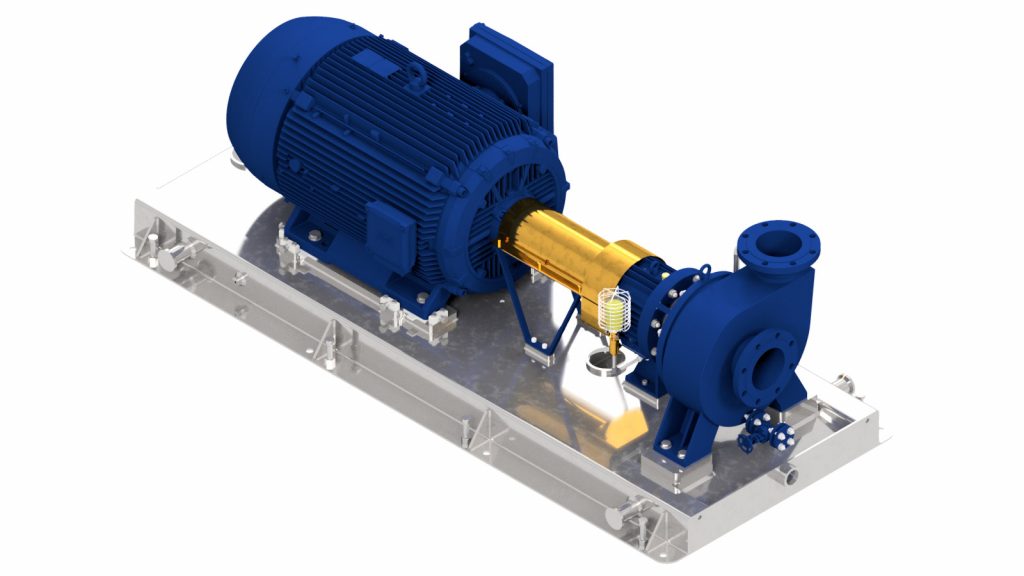

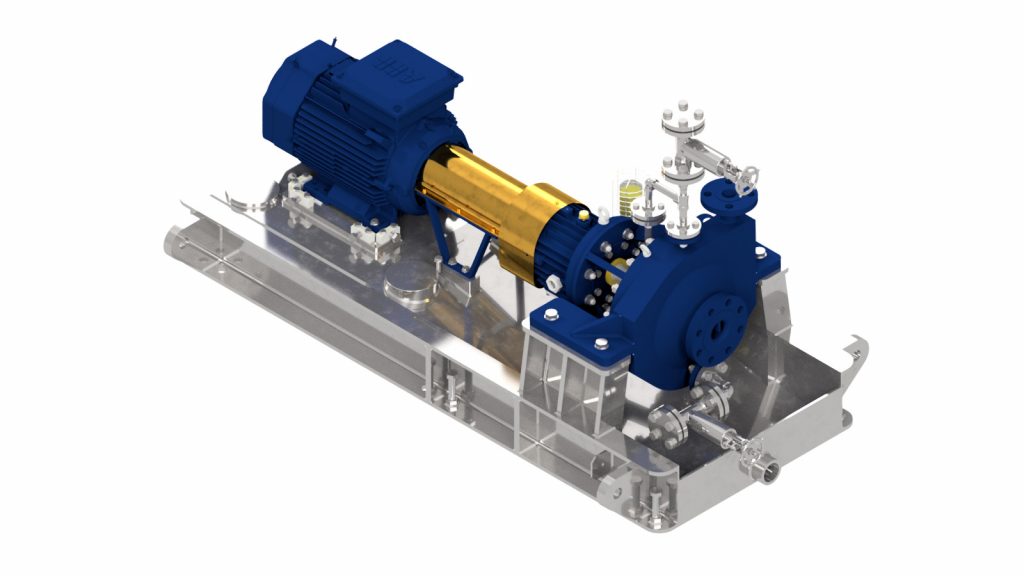

Horizontal Centrifugal Process Pumps

- Manufactured to ISO 5199 and ANSI B73.1 standards.

- Single stage end suction.

- Foot mounted.

- Long coupled.

- Various impeller variations – shrouded, semi-open, open and recessed.

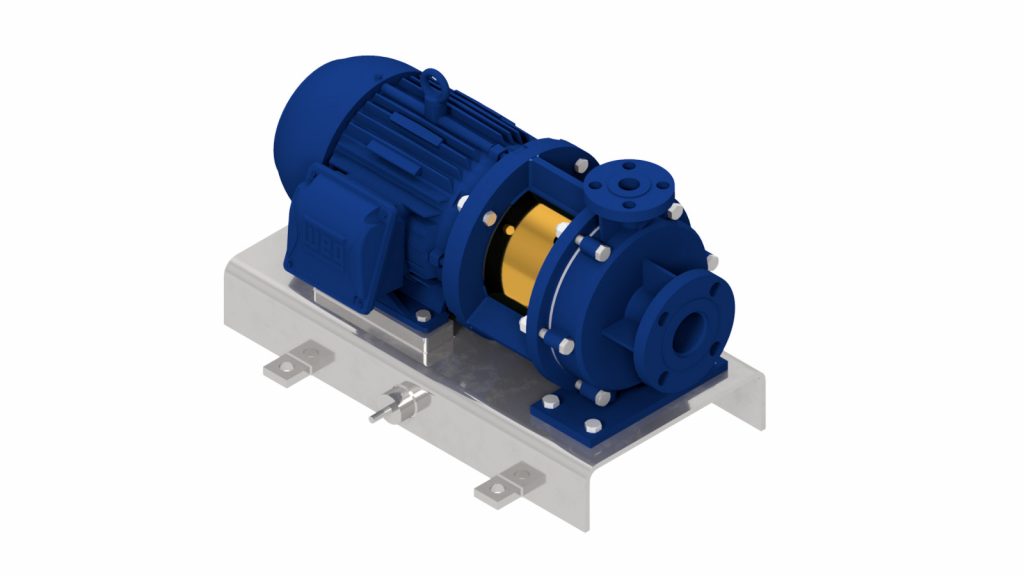

Close-Coupled Pumps

- Single stage end suction.

- Stub shaft mounted on standard motor.

- Compact and cost effective.

- Sub-Base option for back pull out option.

- Various impeller variations – shrouded, semi-open, open and recessed.

Self-Priming Pump

- PATS’ SENATOR range

- Single stage end suction.

- Overhung long-coupled or close-coupled options.

- Suction lift up to 6m.

- Non-metallic construction (machined from solid).

- Close-coupled arrangement, no baseplate, coupling or site alignment required.

- Available with single or double mechanical seals or mag-drive option.

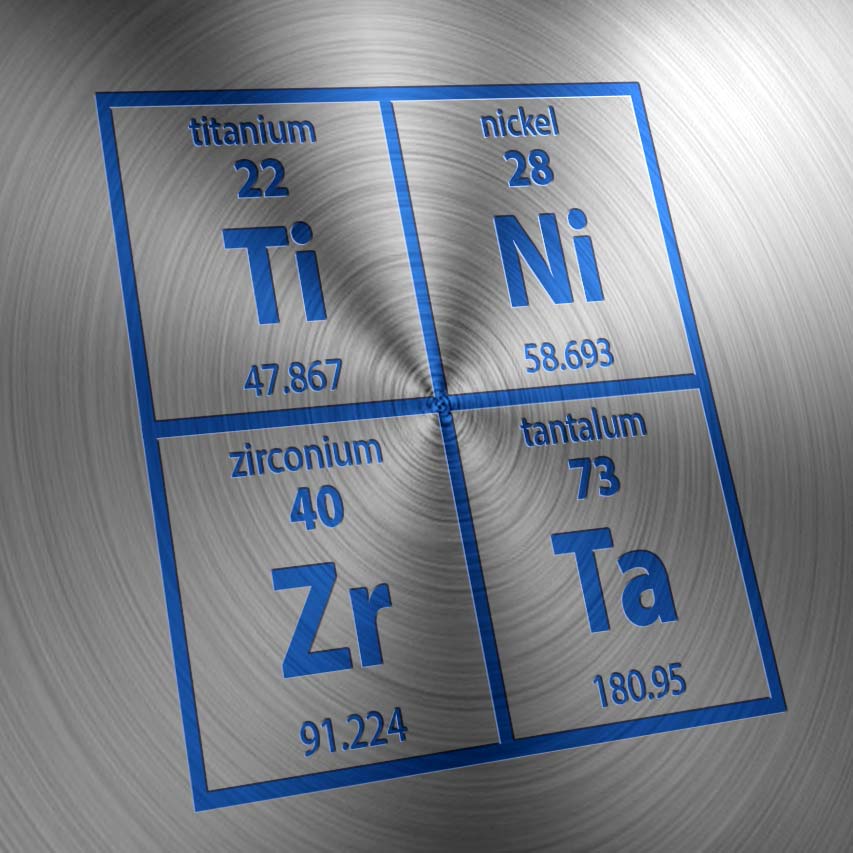

Exotic Materials

- Low Temperature Steels

- 316/316L Dual Certified Stainless Steel

- Titanium

- Zirconium

- Tantalum

- Monel®

- Duplex & Super Duplex

- Inconel® 625

- Incoloy® 825

- Hastelloy®

- Nickel

- Non-Metallics including PP, PVDF, PTFE

Made in Britain – Exported Worldwide

All of our pumps are custom manufactured at our extensive facility in Adlington, South Manchester by highly experienced staff who have been at the forefront of pump design and manufacture for over 40 years.

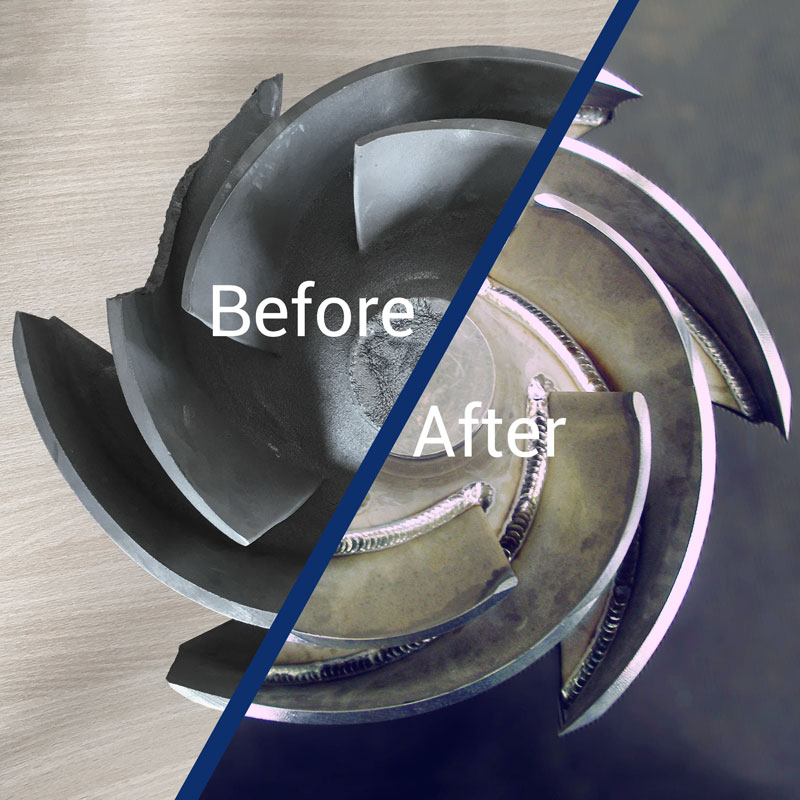

Need Servicing?

As well as manufacturing, PATS also offer comprehensive pump servicing and testing facilities. Strip & report, spare parts supply, reverse engineering, refurbishment, problem analysis and warranty work.

Can we help?

If you would like to discuss an upcoming project with PATS and take advantage of an extensive knowledge base to resolve a specific pump related issue, please get in touch and our team of specialist pump engineers will be happy to help.