Call us: +44 (0)1625 874598 Email us: sales@pumptech.co.uk

Facilities

We carry out a full range of performance testing options from the testing of our own PATS manufactured pumps to independent sub-contract performance testing and research and development testing of many major pump manufacturers’ pumps.

Performance Testing

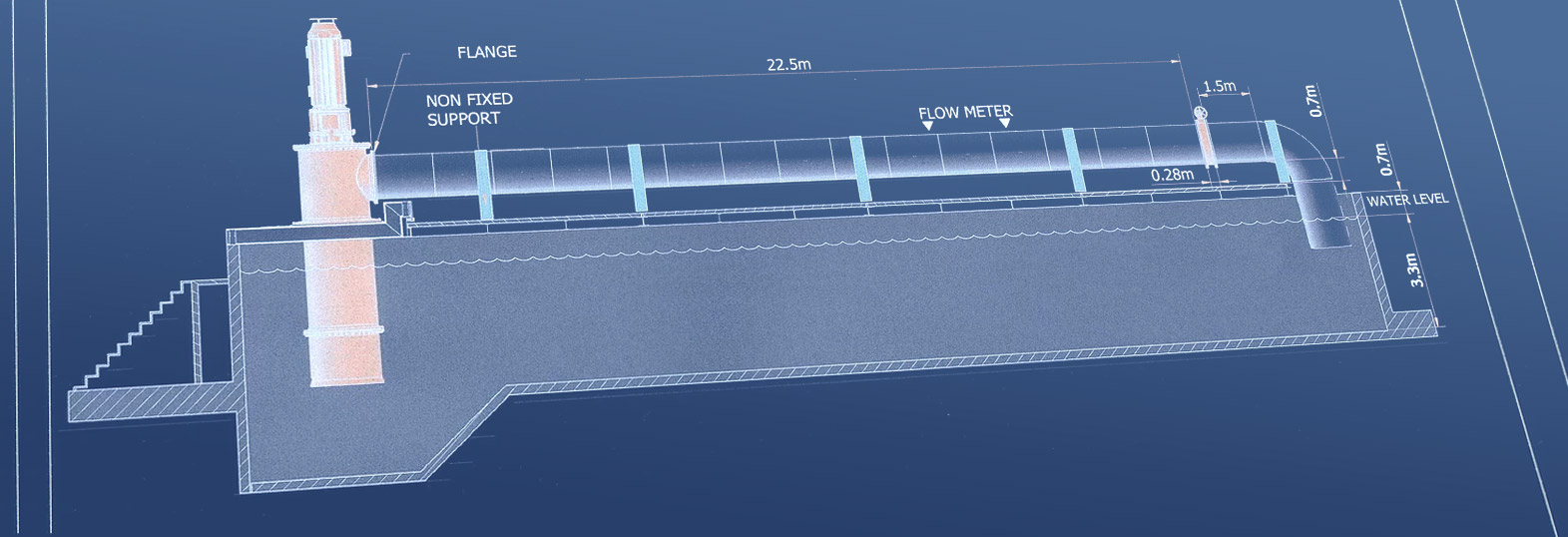

- Full performance testing of all vertical pump designations and submersible pumps using PATS’ vertical test tank.

- Full performance testing of all horizontal pump designations using PATS’ horizontal test rig.

- Performance testing to ISO 9906: 2012 – API 610 specifications.

- Full mechanical run, extended run, condition monitoring and integrity testing.

- NPSH Testing utilising vacuum suppression vessel.

- Testing of complete units and bare-shaft pump arrangements.

- Hydrostatic testing.

Test Capabilities

- Pump Suction Branches up to DN600.

- Pump Discharge Branches up to DN1400.

- Contract specific pipework can be designed and built to order to suit specific test and pressure requirements.

- Flow capabilities of up to 36,000m3/hr (10,000l/s)

- Test tank capacity of 1,000,000 litre tank.

- 8m deep sump with three moveable platforms and no head height limitations to accommodate the majority of pump designs.

- 40 tonne crane provides the ability to handle and install all but the largest of pump-sets.

Test Equipment

We have a range of slave motors up to 1.2MW at 60Hz to cover most testing requirements. Specific motor and generator requirements outside this range can be hired in on a separate contract basis.

- 500kVA Generator

- 400kW VFD

- 250kW Soft Start

- Digital instrumentation for both flow and pressure measurement.

- Power measurement by wireless torque meter or power logger.

- FFT vibration analysis available.

- Load Cells for thrust bearing measurement.

- Full temperature and noise measurement recording also available.

PATS’ test bed facility is immense and can accommodate the largest of VTPs. This is a very useful tool in the determination of pump efficiency, and the production of a pump performance curve.

Rob Paul. Senior Mechanical Engineer. United Utilities

I would have no hesitation in recommending the services of a very professional and accommodating outfit such as PATS

Can we help?

If you would like to discuss an upcoming project with PATS and take advantage of an extensive knowledge base to resolve a specific pump related issue, please get in touch and our team of specialist pump engineers will be happy to help.