Call us: +44 (0)1625 874598 Email us: sales@pumptech.co.uk

Whilst the basic hydraulic and mechanical aspects of our pumps are from established parameters, each unit is custom engineered to suit our clients’ process application. This flexible approach ensures the optimum features essential for trouble free, low maintenance installation.

Particular areas of expertise for built to order equipment include, but are not limited to:

- Low Flow, High Head pump designs

- Low NPSH pump designs

- Recessed Impeller pump designs (vortex flow)

- Externally Tank Mounted VS4 pumps

- Specially Engineered, bespoke, tailor made, designed to order, engineered solution

- Exotic materials (any commercially available raw material)

- Molten Sulphur, Salts & Metals

- Molten Plastics high temperature pumps

- Acid pumps

- High Pressure pump designs

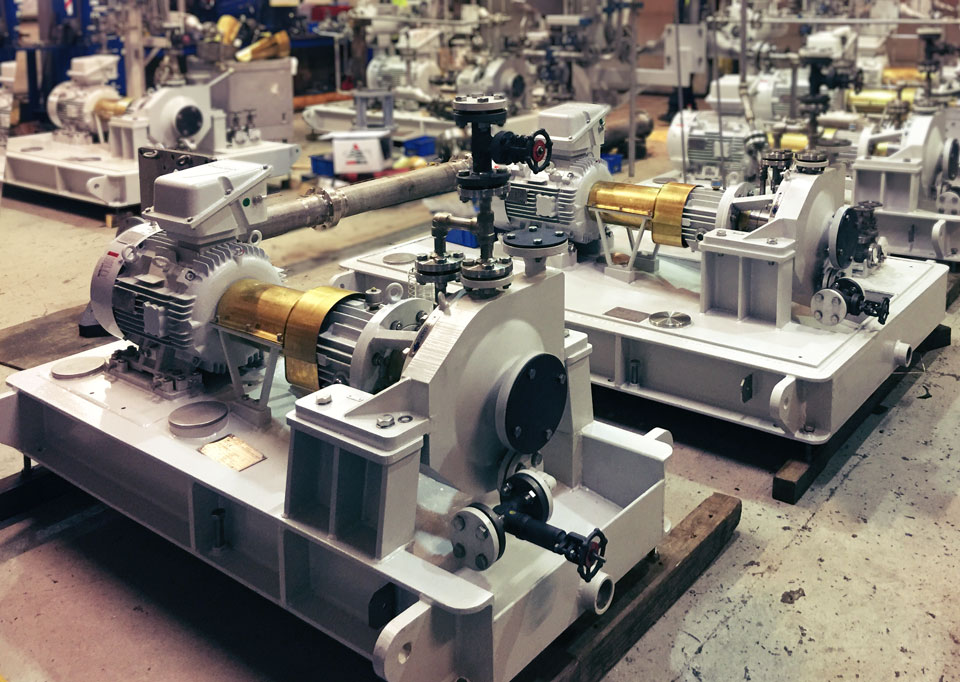

Horizontal Low Flow, High Head Pumps (API 610 OH2)

This range was originally conceived to fulfil a growing market need for low-flow, medium/high head duty requirements utilising proven, uncomplicated, conventional pump hydraulic designs at normal synchronous speeds. Pumps are produced in OH2 designation conforming to API 610 standards, although other specific design requirements can be accommodated.

Circular, concentric casing design reduces radial loads by as much as 85% at low flowrates reducing shaft vibration and extending MTBF, radial bearing and mechanical seal life.

Using 3D printed components combined with our preference for fabricated construction using machined from solid material techniques, the resulting hydraulic end has a greater thickness with up to five times denser, homogenous structure, far stronger and longer lasting than cast components.

Flowrates up to 20m3/hr with differential heads up to 500m are achievable with very advanced impeller eye characteristics enabling very low NPSHR . Due to the normal synchronous speeds, no additional noise attenuation is required.

Molten Salts and Metals Pumps

A major area of PATS’ expertise is in the design and manufacture of steam jacketed pumps for molten sulphur, salts and metals. Over many years PATS has constantly refined the features based on operational experience and customer feedback.

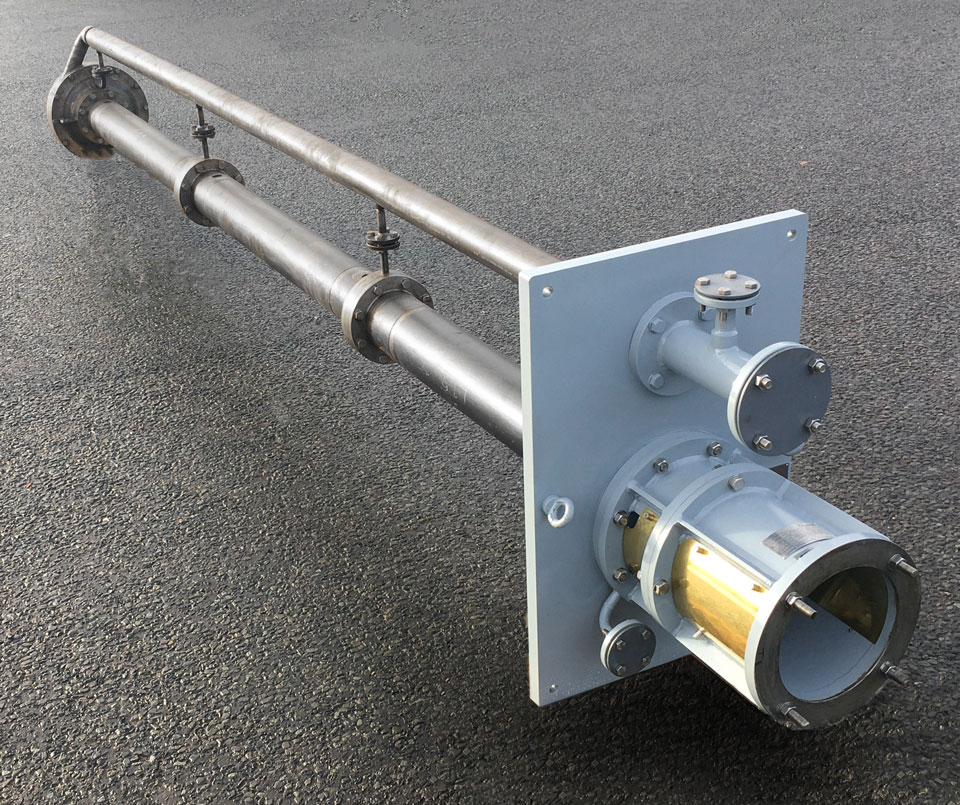

Recessed Impeller Pumps

PATS’ range of Recessed Impeller Pumps have been developed over many years and offer unrivalled clog-free performance and superior low shear capabilities.

The non-clogging wet-end design has no close-running clearances or abrupt changes in direction or velocity, enabling the pumping of large solids, fibrous solids, erosive slurries, and soft clogging slurries without issue. The matched suction and discharge nozzle sizes maximising large solids handling capabilities whilst minimising velocity change.