Call us: +44 (0)1625 874598 Email us: sales@pumptech.co.uk

There are various types of vertically suspended pumps available, below are the types of units which PATS regularly supply.

Whilst the basic hydraulic and mechanical aspects of our pumps are from established parameters, each unit is custom engineered to suit our clients’ process application. This flexible approach ensures the optimum features essential for trouble free, low maintenance installation.

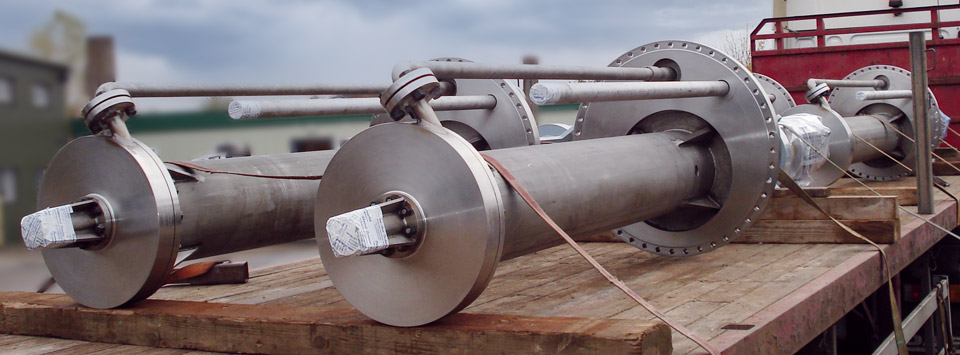

Hydraulic ends are designed for heavy duty service with thicknesses ample to cater for corrosive service. Generally manufactured in “milled-from-solid” format using certified billet materials, the resulting dense material eliminates casting failures and porosity, giving greater service life, whilst still being competitively priced. Casings of concentric, single volute, double volute and diffuser ring designs, impellers of open, semi-open and shrouded designs are all available, as are recessed ‘vortex’ designs to handle large solids concentrations, or for ‘low-shear’ applications. All designed to give minimum NPSH requirements.

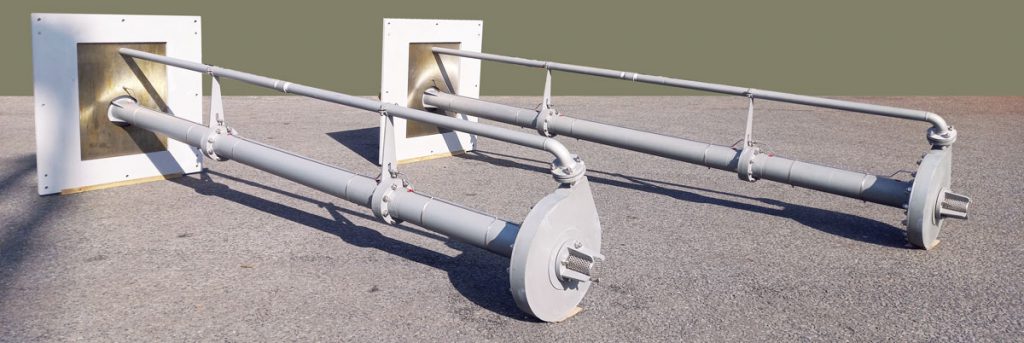

The high demand for specially designed VS4 units has enabled PATS to specialise in this area. PATS’ unique floating bush bearing designs can result in extremely long bearing life and steam jacketed versions for pumping molten liquids are a major part of PATS’ output.

Vertical VS4 pumps with intermediate line-shaft bearings can be supplied in suspended lengths of up to 8 metres in standard format. Specialist designs of 12 metres and beyond can be offered with integral frames.

Bearing lubrication is either by process fluid, if clean and free from solids, or external water flush, oil or grease fed from an automatic grease pump driven off the main shaft.

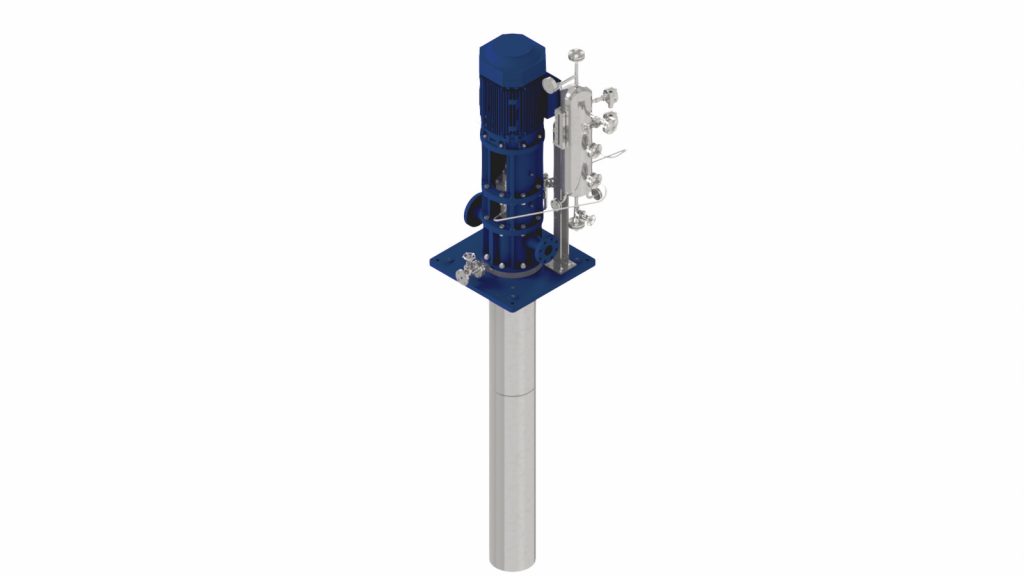

Vertical VS5 pumps without intermediate bearings in ‘cantilever-shaft’ form can be supplied up to 2 metres long depending on speed, radial load and duty conditions. For long service life, the integrity of cantilever shaft pumps depends on the proximity of the first critical speed to the operational speed. PATS’ units are conservatively sized so that they do not run through the first critical speed. The effective length of PATS’ cantilever pumps can be increased by the use of ‘suction tailpipes’ up to 5 metres long, where necessary. PATS has also developed the VS5 unit in that it’s recessed impeller design does not generate any axial or out of balance radial thrust loads.

API 610 Vertical Centrifugal Process Pumps

VS1 Vertical Centrifugal Pump

- ‘Flow through’ casing bowl.

- Higher pressures easily achieved.

- Limitless pit/borehole depth.

- Specialised versions for critical services available.

- Single or multistage designs.

VS2 Vertical Centrifugal Pump

- Wet pit volute casing design.

- High head single stage.

- ‘Flow through’ casing bowl.

- Limitless pit/borehole depth can be accommodated.

- Specialised versions for critical services available.

VS3 Vertical Centrifugal Pump

- ‘Flow through’ casing bowl.

- Axial-flow hydraulics.

- Higher flow rates easily achieved.

- Low head.

- Limitless pit/borehole depth can be accommodated.

- Specialised versions for critical services available.

VS4 Vertically Suspended Line-Shaft

- Non-pressurised shaft entry point.

- Suitable for restricted emissions applications.

- PATS’ unique floating bush bearing design.

- Steam jacketed version for molten liquids.

- Lineshaft bearings available in various materials.

- Bearings – product feed lubricated if required.

- Bearings – clean feed available.

- Bearings – grease pump systems available.

VS5 Cantilever Sump Pump Vertically Suspended

- Unlike VS4 has no shaft bearings below mounting plate.

- Known as ‘cantilever shaft’ pump.

- Ideal for slurry pumping.

- Small sump variation – direct motor mount construction.

- Recessed impeller hydraulic end variation.

- PATS unique recessed impeller design.

VS6 Double Casing Diffuser Vertically Suspended Pump

- ‘Flow through’ casing bowl.

- Higher pressures easily achieved.

- Higher flows available.

- As VS1 but with outer casing.

- Specialised versions for critical services available.

- Multiple stages available.

VS7 Double Casing Volute Vertically Suspended Pump

- Volute casing.

- Higher pressures easily achieved.

- ‘Flow through’ casing bowl.

- Specialised versions for critical services available.

- As VS2 but with outer casing.

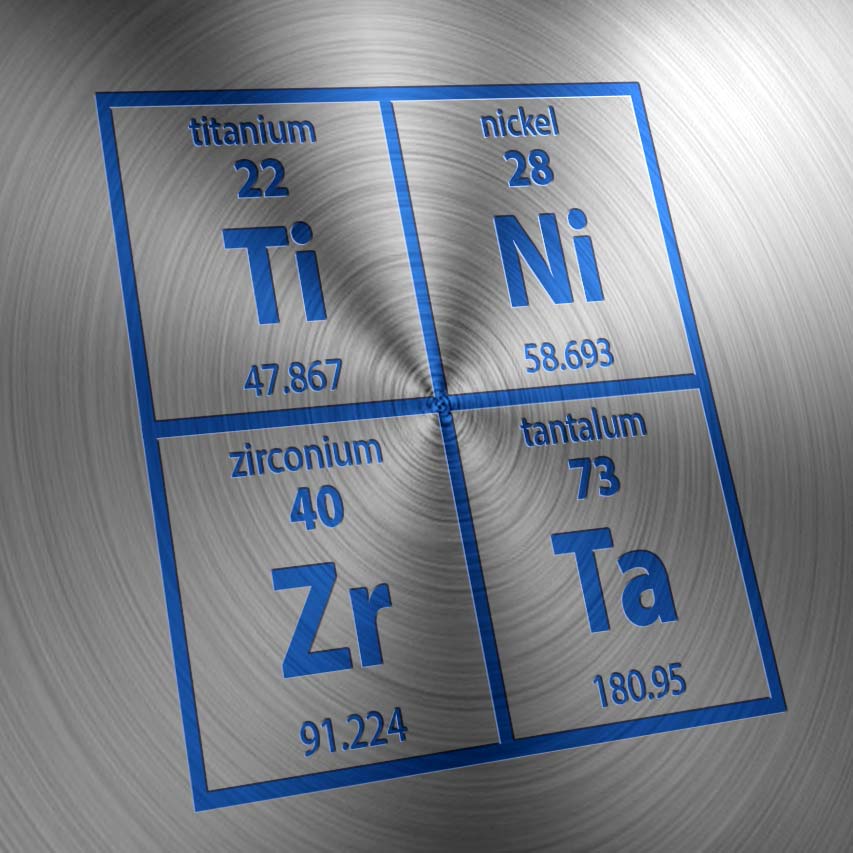

Exotic Materials

- Low Temperature Steels

- 316/316L Dual Certified Stainless Steel

- Titanium

- Zirconium

- Tantalum

- Monel®

- Duplex & Super Duplex

- Inconel® 625

- Incoloy® 825

- Hastelloy®

- Nickel

- Non-Metallics including PP, PVDF, PTFE

Made in Britain – Exported Worldwide

All of our pumps are custom manufactured at our extensive facility in Adlington, South Manchester by highly experienced staff who have been at the forefront of pump design and manufacture for over 40 years.

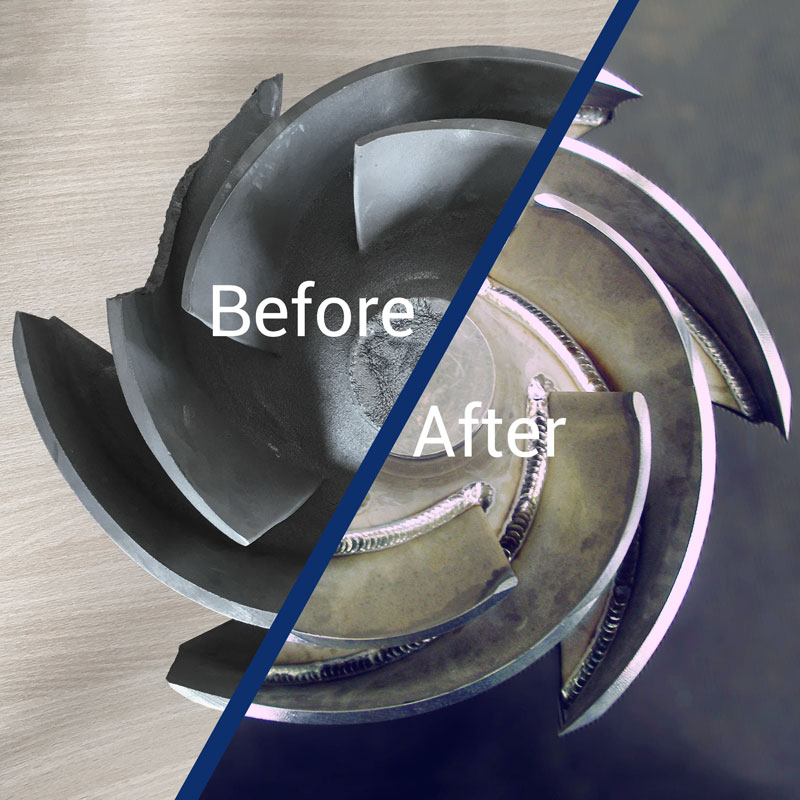

Need Servicing?

As well as manufacturing, PATS also offer comprehensive pump servicing and testing facilities. Strip & report, spare parts supply, reverse engineering, refurbishment, problem analysis and warranty work.

Can we help?

If you would like to discuss an upcoming project with PATS and take advantage of an extensive knowledge base to resolve a specific pump related issue, please get in touch and our team of specialist pump engineers will be happy to help.