Call us: +44 (0)1625 874598 Email us: sales@pumptech.co.uk

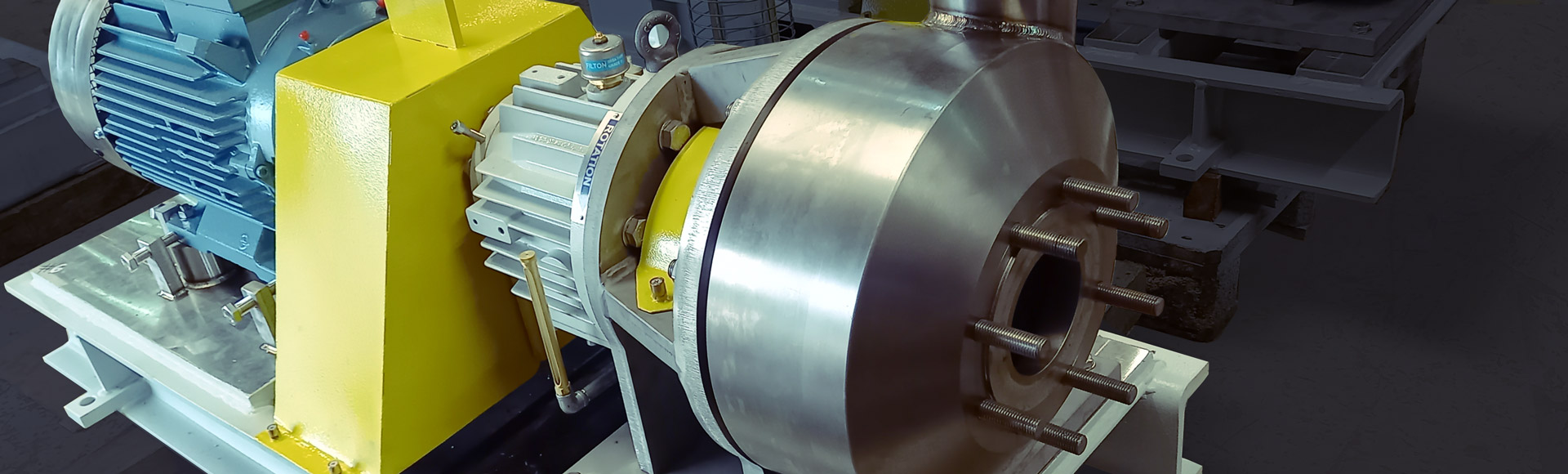

PATS’ range of Recessed Impeller Pumps have been developed over many years and are designed to offer unrivalled clog-free performance and superior low shear capabilities.

The non-clogging wet-end design has no close running clearances or abrupt changes in direction or velocity enabling the pumping of large solids, fibrous solids, erosive slurries and soft clogging slurries without issue. The matched suction and discharge nozzle sizes maximising large solids handling capabilities whilst minimising velocity change.

Principle of Operation

- The impeller develops a vortex within the casing that is entirely out of the flow path of the impeller, creating a fluid stream within the open casing with nothing to impede the flow.

- The impeller vortex of fluid mass extends towards the suction. The vortex produced draws the particles/solids into the fluid stream.

- These particles/solids swirl into the fast moving vortex within the pump casing.

- The majority of solids/particles are discharged in less than one revolution due to centrifugal force induced by the vortex action, the liquid stream being the main propulsive force. The majority of solid material seldom touches the impeller itself.

Unique Design

Historically, one of the primary issues with recessed impeller pumps was the fact that the cupped impeller design produced very high axial thrust loads. To overcome this, manufacturers simply added additional thrust bearings to withstand the high thrust loads rather than overcoming the root of the problem. PATS’ recessed impeller pumps have a unique impeller design that has completely eliminated the issue of axial thrust loads, whilst maximizing hydraulic efficiency. The impellers provide exceptional gas handling properties and offer extremely long service life essential for a trouble free, low maintenance installation.

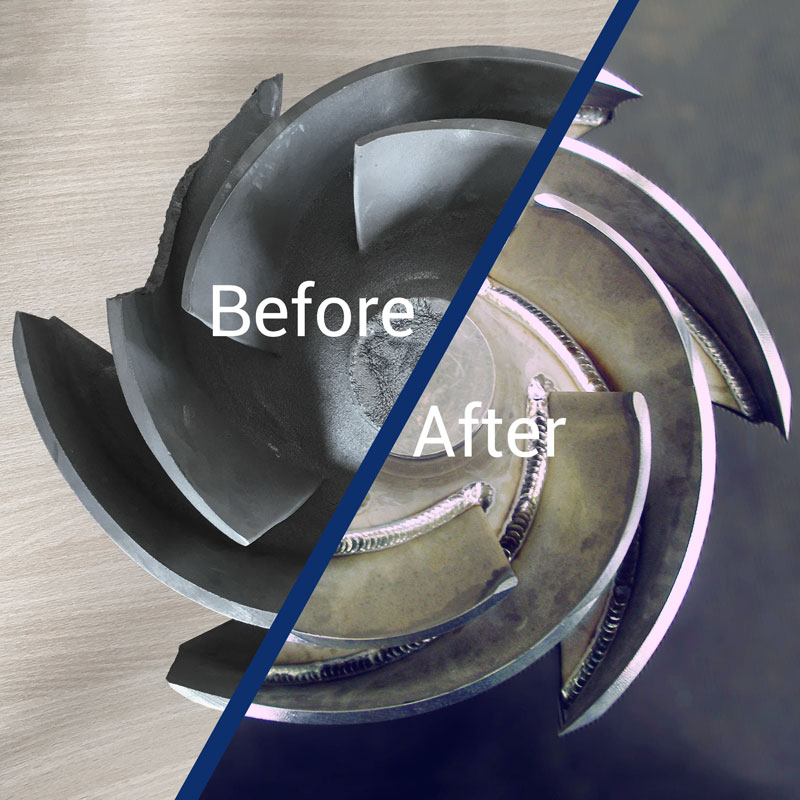

Superior abrasion resistance is maintained by the unique casing and impeller design which imparts the vortex action causing very little solid content to come into contact with the impeller, minimising abrasive wear and maintaining solids integrity.

The low shear capabilities of the pump allow delicate solids to be pumped in liquid suspension without damage and minimal emulsification of either separated liquids or shear sensitive liquids.

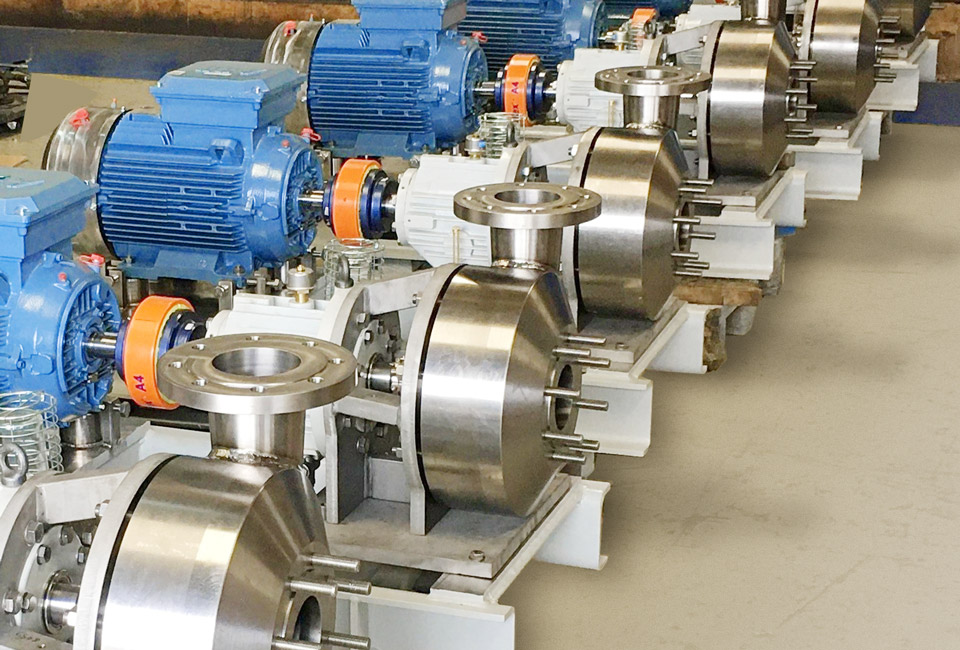

PATS’ recessed impeller pump designs are available in both horizontal and vertical configurations and can be supplied to API 610 11th Edition for the petrochemical, oil and gas markets or ISO 5199/ANSI B73.1 standards for chemical and industrial markets. As with all PATS pump designs the recessed impeller pumps are also available in all commercially available materials.

Can we help?

If you would like to discuss an upcoming project with PATS and take advantage of an extensive knowledge base to resolve a specific pump related issue, please get in touch and our team of specialist pump engineers will be happy to help.

Made in Britain – Exported Worldwide

All of our pumps are custom manufactured at our extensive facility in Adlington, South Manchester by highly experienced staff who have been at the forefront of pump design and manufacture for over 40 years.

Need Servicing?

As well as manufacturing, PATS also offer comprehensive pump servicing and testing facilities. Strip & report, spare parts supply, reverse engineering, refurbishment, problem analysis and warranty work.